About our Journey

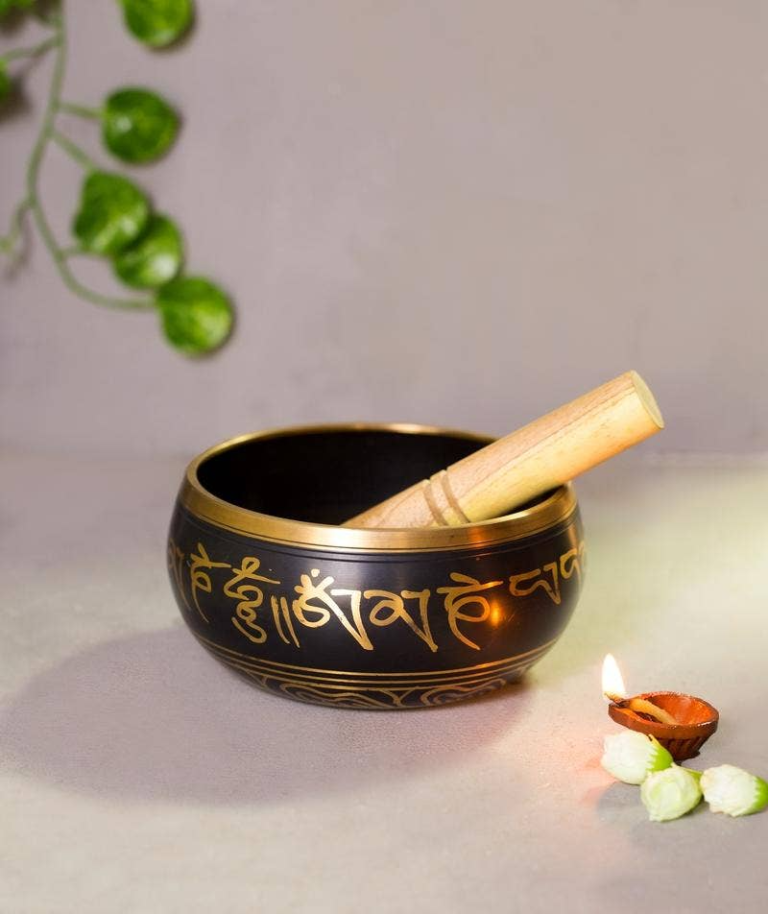

Singing Bowl Exports is a trusted name in the world of traditional craftsmanship and spiritual exports. As a manufacturer and exporter, we specialize in a wide range of handmade singing bowls, antique-style god statues, and a variety of miscellaneous spiritual and decorative items that embody heritage, artistry, and devotion.

At Singing Bowl Exports, we specialize in a wide range of authentic, handmade singing bowls, antique-style god statues, and a variety of other spiritual and decorative items. Each product is a testament to our commitment to craftsmanship, combining intricate design with deep spiritual significance. Whether it’s the soothing vibrations of our singing bowls, the divine presence of our god statues, or the unique appeal of our decorative items, every piece we offer is created with devotion, skill, and a deep respect for tradition.

Our Products

What materials are used in the manufacture of a Therapy Singing Bowl ?

Only high-quality and, above all, pure metals are used in the production of Therapy Singing Bowls . The use of high-quality metals naturally also means higher manufacturing costs, but it guarantees the exceptional and optimal sound and vibration quality.

The main components of the bronze alloy used to make singing bowls are copper and tin. Other pure metals are added in small quantities. To pay tribute to the traditional blacksmith’s art of earlier times, we add a piece of an old Singing Bowl to each alloy melt.

Good to know

Incidentally, such alloys have been used since the Bronze Age, i.e. for thousands of years – for church bells, for example. They are known for their strength, hardness and corrosion resistance.

1. Production of the bronze alloy

In the blast furnace, the various metals are melted into a high-quality bronze alloy. The highest possible tin content is essential for the high sound quality. At the same time, the tin makes the forging process more difficult. Accordingly, it takes specialist knowledge and a great deal of experience to determine exactly the right proportion of this expensive metal.

2. Casting the singing bowl blanks

In the next step, blanks are cast from the molten metal in a special, lenticular mold. Once the alloy has solidified, they are removed from the molds and tested for their suitability for further processing.

3. Forging the Singing Bowl

A Singing Bowl is then forged, i.e. shaped, from the freshly cast blank using traditional forging tools. Depending on the type of singing bowl, at least 25 forging sessions with thousands of hammer blows are required until the final shape is achieved. Four to six experienced blacksmiths work on a bowl at the same time. A blacksmith uses long tongs to ensure that the red-hot metal is continuously turned during the forging process so that the Singing Bowl can be forged evenly. He also keeps an eye on the forge fire so that the cooling alloy can be reheated if necessary. This can be necessary up to 100 times during the entire process for larger Singing Bowls . The other blacksmiths hammer the red-hot metal disc into a uniformly shaped bowl in perfect rhythm with countless hammer blows. Once the Singing Bowl has reached its final shape, it is quenched in a cold liquid.

4. Fine tuning of the Singing Bowl

The next step is to fine-tune the Singing Bowl with special hammers. Various forging techniques are used to precisely shape the form, sound and vibration.

5. Cleaning the Singing Bowl

Oxides or slag can remain on the surface of the Singing Bowl from the melting and forging process, for example. The bowl is first roughly cleaned using simple mechanical means and then scraped out by hand. This procedure further contributes to perfecting the sound and vibration behavior.

6. Polishing the Singing Bowl

We use a special ash mixture for the final polish of the Singing Bowl . Rice straw and mustard oil are burnt and mixed into a creamy paste. This mixture is used to carefully polish the Singing Bowl for several minutes to remove any remaining impurities. This final step also gives the Singing Bowl its typical shiny surface.

The manufacturing process is completed when the Singing Bowl is polished. Some therapy singing bowls are additionally sealed in Germany with a permanent coating, which provides an additional protective barrier. This is recommended for certain work areas.

Good to know

Only this “standardization” of the singing bowl types made it possible to communicate the Therapy Bowls sound massage and sound methods safely and uniformly and to research their effects. Today we know quite precisely which Singing Bowl appeals particularly well to which parts of the body. Nevertheless, every Singing Bowl is and remains unique, just as every sound experience is always unique. A certain range of sound and vibration within the types is therefore absolutely desirable in order to meet people’s individual needs and preferences.

Therapy Singing Bowls with permanent coating at a glance

Uncomplicated application in combination with oils, water or disinfectants

Very easy to clean

Easy to clean

Can be easily disinfected

Odorless

No repolishing necessary

Permanently glossy surface of the Singing Bowl

In these cases, we recommend the permanent coating

When using Singing Bowls directly on the skin

If the Singing Bowl needs to be disinfected frequently

If the bowl often comes into contact with water, especially salt or chlorinated water

Generally for use in nursing homes, hospitals and spas